Products »

Hot Work Tool Steels

HG 2344 (DIN 1.2344, AISI H13, SKD61)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V |

| 0.32-0.45 | 0.20-0.60 | 0.80-1.25 | ≤0.03 | ≤0.03 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

| +/-0.02 | +/-0.04 | +/-0.05 | +/-0.005 | +/-0.005 | +/-0.10 | +/-0.05 | +/-0.05 |

2) Application

Typical applications include die casting dies for aluminium, magnesium and zinc, extrusion dies for aluminium and brass, liners, mandrels, pressure pads, followers, bolsters, die cases, die holders and adaptor rings for copper and brass extrusion. H13 is used to produce hot stamping and press forge dies, split hot heading dies, gripper dies, hot punching, piercing and trimming tools. Other applications include plastic moulds, shear blades for hot work and hot swaging dies.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Preheat slowly to 750°C then increase the temperature more rapidly to 1050-1100°C. Do not forge below 850°C. It is essential to cool the H13 slowly after forging, either in a furnace or in vermiculite.

5) Heat treatment

Annealing

Soak thoroughly at 840-860°C before furnace cooling at a maximum rate of 20°C per hour down to 600°C followed by cooling in air. Its maximum hardness can reach 229HB

Stress Relieving

When tools made from H13 tool steel are heavily machined or ground, the relief of internal strains is advisable before hardening to minimise the possibility of distortion. Stress relieving should be done after rough machining. To stress relieve, heat the component carefully to 700°C, allow a good soaking period (two hours per 25mm of ruling section). Cool in the furnace or in air. The tools may then be finish machined before hardening.

Hardening

Preheat to 780-820°C. Soak thoroughly, and then increase rapidly to the final hardening temperature of 1000-1030°C. When the H13 has attained this temperature, soak for approximately thirty minutes. Cool in air. Large sections may be quenched in oil. To reduce scaling or decarburisation, we recommend isothermal molten salt bath treatment. Preheat in salt at 780-820°C then transfer to salt bath standing at 1000-1030°C. Soak and quench into salt standing at 500-550°C. Allow to equalise, withdraw and cool in air. Alternatively, this tool steel may be vacuum hardened or pack hardened. Tools should be tempered as soon as they become hand warm. Its hardness can reach HRC51.

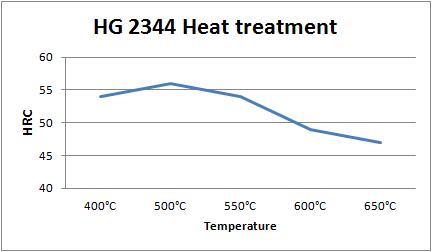

Tempering

Heat uniformly to the required temperature allowing a soaking time of two hours per 25mm of ruling section. Withdraw from the furnace and allow cooling in air. A second tempering is strongly recommended, the H13 tool being allowed to cool to room temperature between tempers. The usual tempering range is 530-650°C depending on the hardness requirements and the operating temperature of the tool. Hardness after hardening and tempering is as following table:

| Temperature | 400°C | 500°C | 550°C | 600°C | 650°C |

| HRC | 54 | 56 | 54 | 49 | 47 |

HG 2714(DIN 1.2714,EN 55CrMo8,56NiCrMoV7, L6)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | Ni | V |

| 0.50-0.60 | 0.60-0.90 | 0.10-0.40 | ≤0.03 | ≤0.03 | 0.80-1.20 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 |

| +/-0.03 | +/-0.04 | +/-0.03 | +/-0.005 | +/-0.005 | +/-0.05 | +/-0.04 | +/-0.05 | +/-0.02 |

2) Application

Punches and dies, cold forming tools, and coining dies.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Preheat at 650-680°C before raising the temperature to 850-1050°C and soak until uniformly heated.

5) Heat treatment

Annealing

Heat to 650-700°C, cool slowly in furnace. This will produce a maximum Brinell hardness of 248.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650°C, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Oil: Harden from a temperature of 830-870°C followed by oil quenching. Hardness after quenching is 58 HRC.

Air: Harden from a temperature of 830-900°C followed by air quenching. Hardness after quenching is 56 HRC.

Hardness after hardening and tempering is as following table:

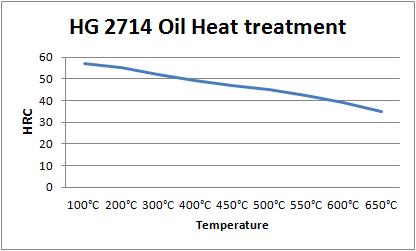

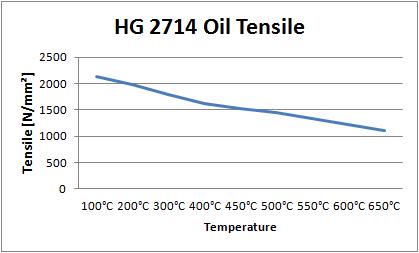

Quenching in oil:

Tempering Temperature (°C) vs. Hardness (HRC) vs. Hardness (HRC) vs. Tensile Strength (N/mm²)

| Temperature | 100°C | 200°C | 300°C | 400°C | 450°C | 500°C | 550°C | 600°C | 650°C |

| HRC | 57 | 55 | 52 | 49 | 47 | 45 | 42.5 | 39 | 35 |

| Tensile Strength | 2140 | 1980 | 1790 | 1620 | 1530 | 1440 | 1345 | 1230 | 1110 |

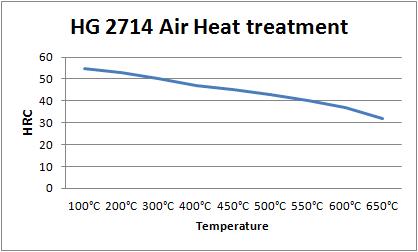

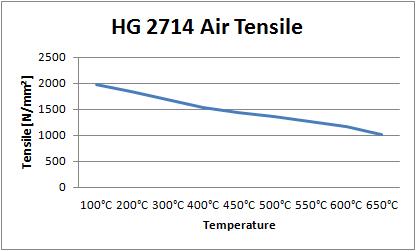

Quenching in air:

Tempering Temperature (°C) vs. Hardness (HRC) vs. Hardness (HRC) vs. Tensile Strength (N/mm²)

| Temperature | 100°C | 200°C | 300°C | 400°C | 450°C | 500°C | 550°C | 600°C | 650°C |

| HRC | 55 | 53 | 50 | 47 | 45 | 43 | 40 | 37 | 32 |

| Tensile Strength | 1980 | 1845 | 1680 | 1530 | 1440 | 1360 | 1260 | 1170 | 1020 |

H HG 2367(DIN 1.2367, X38CrMoV5-3)

1) Chemical Composition and its permissible allowance as per DIN EN ISO4957: %

| C | Mn | Si | P | S | Cr | Mo | V |

| 0.35-0.40 | 0.30-0.50 | 0.30-0.50 | ≤0.03 | ≤0.02 | 4.80-5.20 | 2.70-3.20 | 0.40-0.60 |

| +/-0.03 | +/-0.04 | +/-0.03 | +/-0.005 | +/-0.005 | +/-0.10 | +/-0.10 | +/-0.04 |

2) Application

Wear resisting tools, pressure die casting tools, pressing tools for light and heavy metal.

3) Size range

| Hot rolled, mm | Forged, mm | Tolerance | |

| Round | Dia6-Dia90 XRL | Dia80-Dia503X RL | EN10060 for hot rolled; DIN7527/6 for forged black; En10278 H9 or H11 for peeled round; +3mm/-0 for forged turned |

| Flat & block | 6-90X60-805XRL | 90-450X90-610XRL | EN10058 for hot rolled; +5mm/-0 in thickness and +15/-0 in width for forged black; +3mm/-0 in thickness and +10/-0 in width for forged black for Forged milled |

4) Forging

Hot forming temperature: 1080-900°C.

5) Heat treatment

Annealing

Heat to 800-840°C, cool slowly in furnace. This will produce a maximum Brinell hardness of 235.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650°C, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 1030-1080°C followed by air, oil or warm bath (500-550°C) quenching. Hardness after quenching is 53-57 HRC.

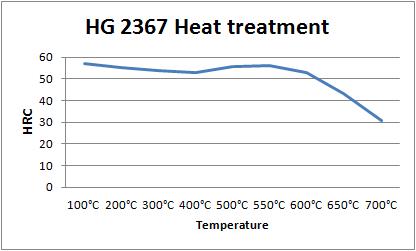

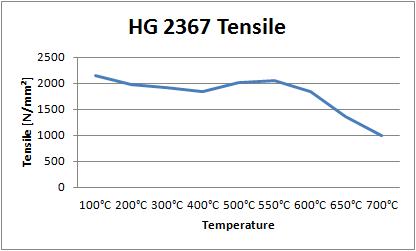

Hardness after hardening and tempering is as following table:

Tempering Temperature (°C) vs. Hardness (HRC) vs. Hardness (HRC) vs. Tensile Strength (N/mm²)

| Temperature | 100°C | 200°C | 300°C | 400°C | 500°C | 550°C | 600°C | 650°C | 700°C |

| HRC | 57 | 55 | 54 | 53 | 55.5 | 56 | 53 | 43 | 31 |

| Tensile Strength | 2140 | 1980 | 1910 | 1845 | 2010 | 2050 | 1845 | 1360 | 995 |

| C | Mn | Si | P | S | Cr | Mo | V |

| 0.33-0.43 | 0.20-0.60 | 0.80-1.25 | ≤0.03 | ≤0.03 | 4.75-5.50 | 1.10-1.60 | 0.30-0.60 |